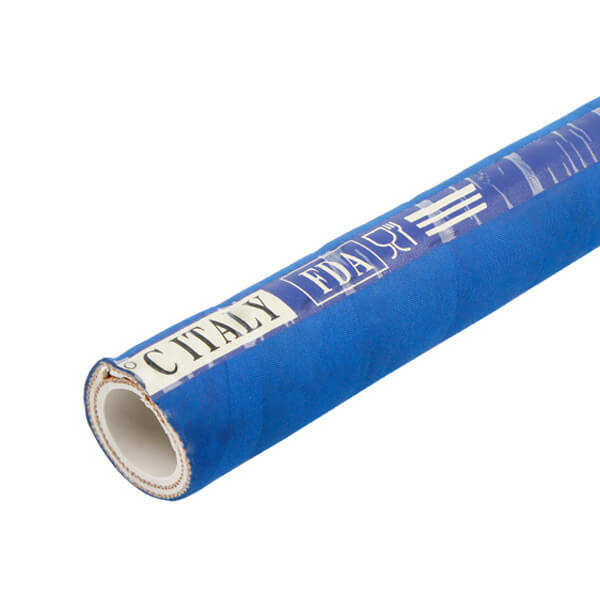

RUBBER FOOD GRADE HOSES

DRS Food Grade rubber hoses must meet stringent safety and hygiene standards to ensure that the transported materials remain uncontaminated. . Here are some key points about DRS rubber food-grade hoses:

Inner Tube: The inner tube of food-grade hoses is typically made of high-quality, non-toxic rubber materials that are suitable for contact with food and beverage products. This helps prevent any leaching or contamination of the transported materials.

Cover: The outer cover is also made of food-grade rubber or other materials that are resistant to abrasion and can withstand the conditions of the specific application.

Rubber food-grade hoses are used in a variety of applications within the food and beverage industry. This includes the transfer of liquids such as water, milk, fruit juices, beer, wine, and other consumable products.

Food-grade hoses need to be flexible for easy handling and maneuverability. They should also be resistant to kinking and crushing to maintain a smooth flow of materials.

These hoses are designed to withstand a range of temperatures, ensuring they can be used in various food processing and handling applications. Some hoses are suitable for both hot and cold liquids.

Food-grade hoses must be easy to clean and sterilize to maintain sanitary conditions. They should be resistant to bacteria and microbial growth and should allow for standard cleaning processes like CIP (Clean-In-Place).

When selecting a rubber food-grade hose, it's essential to consider the specific requirements of the application, including the type of food or beverage being transported, the temperature conditions, and any regulatory standards that must be met. Regular inspection and proper maintenance are crucial to ensure the continued safety and effectiveness of these hoses in food processing and handling operations.